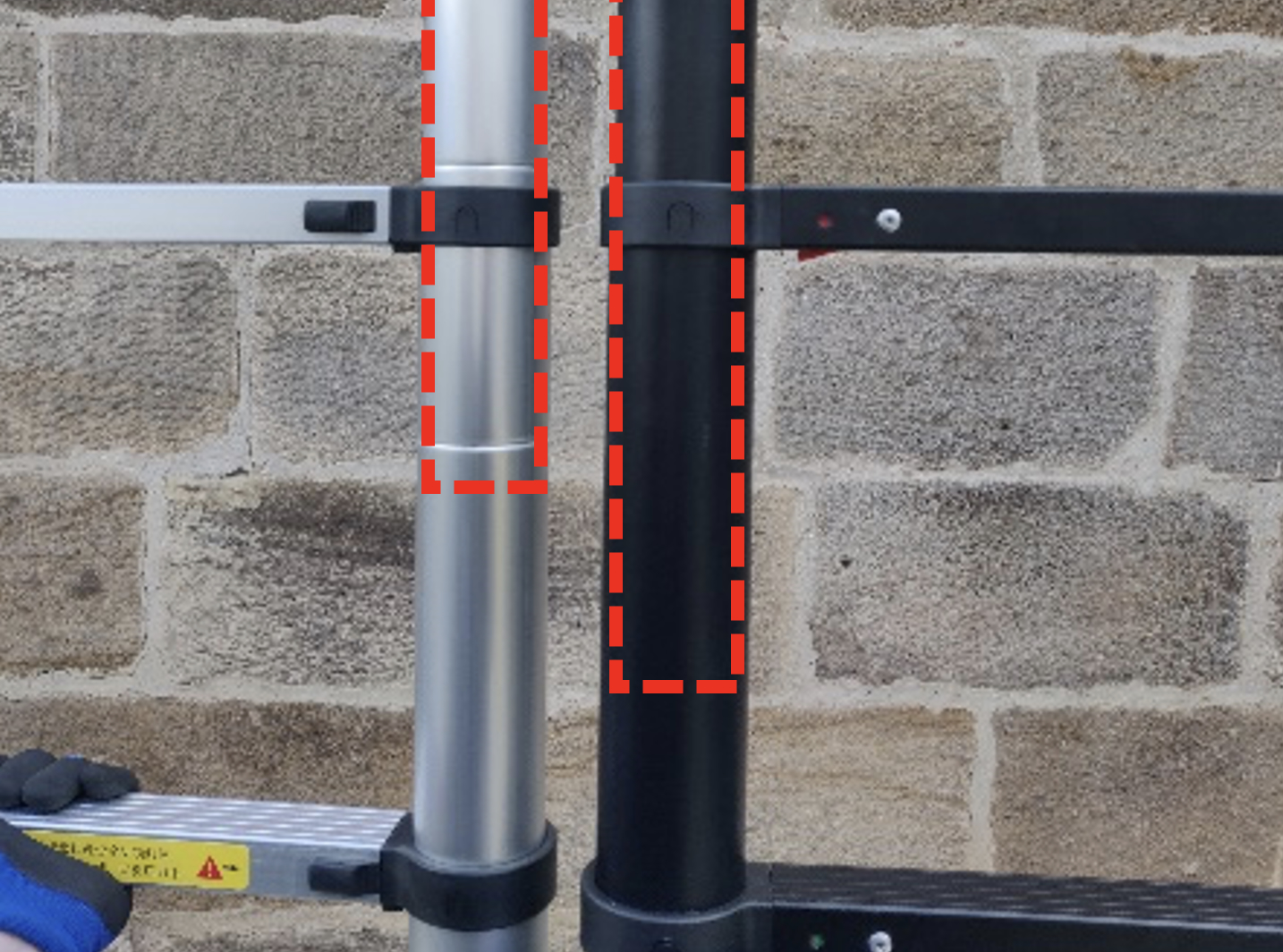

This is possible for many ladder models. The ladder must meet the following criteria:

- The spar must be round

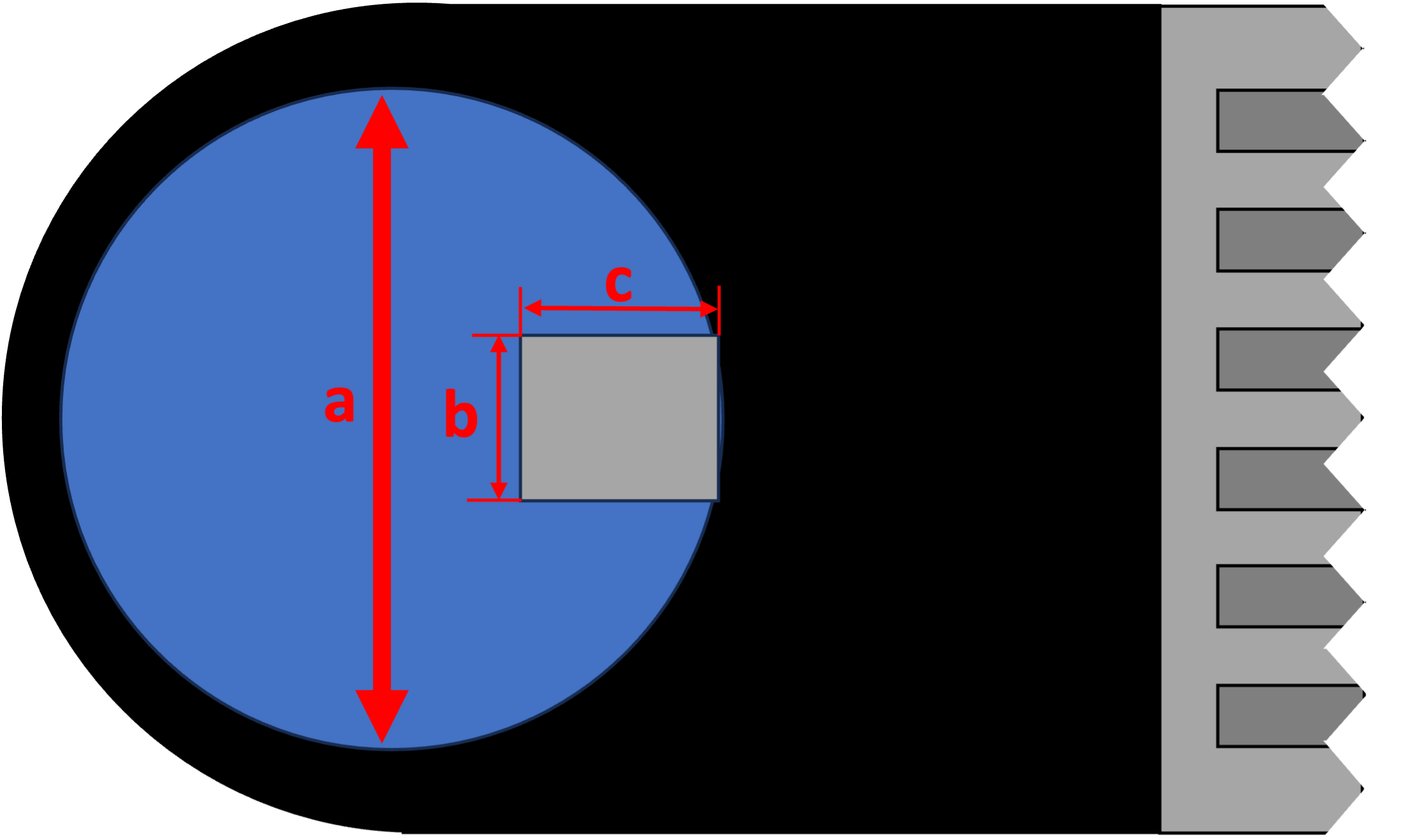

- If you remove the caps at the top, the inside diameter of the top spar must be 28 mm or 32 mm. Attention: Sometimes there is a small number on the plastic part, this is usually the outer diameter of the spar. Don’t let this confuse you and measure instead. The inner diameter is usually 4 mm smaller than the outer diameter.

- There must be an 8 mm spring-loaded button on the inside of the stile of the top step. Without the Leitertec system, this has no use (at the top level), which is why some manufacturers omit the push button.

This must protrude at least 5 mm for 28 mm uprights (inner diameter) and at least 7 mm for 32 mm uprights (see table).

| Inner diameter spar: a | 28 mm | 32 mm |

| Diameter push button: b | 8 mm | 8 mm |

| Push button length: c | >5 mm | >7 mm |

In short: it’s not the same ladder!

Different models often look very similar on the outside, but there are major differences in quality that become apparent when using them.

- Length of the individual telescopic elements:

When extended, the stiles overlap inside the ladder. Our ladder has a stile length of 520 mm. With a step height of 300 mm, the stiles therefore overlap by 220 mm. Cheaper ladders start at 120 mm overlap.

The up to 175% higher overlap is clearly noticeable in the stability when using the ladder. A picture is worth a thousand words:

- Tested in accordance with European standard for telescopic ladders EN131-6

Many ladder manufacturers advertise with a TÜV seal or standard conformity. If you ask more closely, however, this very often results in no reliable comment, or the TÜV certification is not for the whole ladder as you would think, but only a small part of it, such as the packaging process is certified.

We do not want to deceive our customers, but our ladder has been tested and certified by an independent testing institute (SGS)! - Softclose system:

The ladder retracts with air suspension, which significantly reduces the risk of injury. - Significantly larger spar diameter:

Like the stile length, this contributes to the stability of the ladder. Both in bending and in stability when twisted. Our ladders have a stile diameter of 36 mm for the top step, compared to 28 mm for cheaper ladders. Of course, this also makes all subsequent spars thicker/sturdier. - High-quality black powder coating

The black ladders are a real eye-catcher in terms of design and match the Leitertec system! In addition, the coating protects the aluminum and the ladder cannot rust. - Rivets on each step

- Traverse at > 3 m ladders

From 3 m, a stand extension is mandatory, which we offer with our 3.8 m model. - Quality inspection

Every single ladder is individually tested and approved by us. - Release for trade

All of the above measures mean that the ladder is approved for both private and commercial use. This underlines once again that we do not want to compromise on quality.

We offer a very high quality product, for which the above points are necessary, but which make the ladder more expensive due to more material/processes/tests. We stand behind our product and are proud to be able to offer it to you!

On caravans with hammered sheet metal or other very rough surfaces, the suction cups cannot build up their vacuum. But rubber has the property of having a higher coefficient of friction at higher pressure. This means that the weight of the user makes the ladder much more stable than without the Leitertec system. In addition to the increased contact surface, this results in very similar usage results to smooth surfaces.

Unfortunately, this sometimes happens with the 28 mm Leitertec system. This is no longer possible with the 32 mm system.

It requires dexterity, but it is possible to press sideways with a knife past the arm on the spring pressure pin and push it backwards.

Alternatively, a wire can be inserted through the hole from the outside to push the spring pressure pin backwards.

If both options do not work, the only remaining option is to drill a small hole in the center of the plastic (there is already a hole in the aluminum) and use a wire to push the spring pressure pin backwards. The hole only needs to be big enough for the wire to fit through.

Yes, we will pay the shipping costs! Only return costs (except for warranty cases) are borne by the customer.

Yes, the ladder is approved for both private and commercial use.

Absolutely normal! The small scratches that you notice on your telescopic ladder are the result of the repeated extension and retraction of the moving parts during the manufacturing and testing process. Each ladder is individually checked for quality, and this repeated running in and out is a crucial part of the process. These scratches are superficial and have no effect on the structural integrity or performance of your ladder.

On the contrary, they are a sign of the quality control to which each telescopic ladder is subjected and, hopefully, of intensive use on your part. Therefore, consider the small scratches as a positive sign that your telescopic ladder has been thoroughly checked and is ready to provide you with safe and reliable use. To avoid deep scratches, clean the ladder regularly.

If the scratches still bother you too much, they can be easily touched up with a spray can. You are welcome to ask us for a suitable spray can.

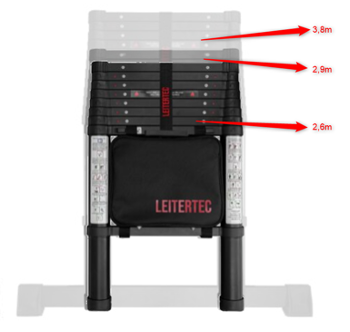

We recommend choosing the right ladder height for your motorhome:

- 2 m telescopic ladder: For motorhomes up to 2.2 m high.

- 2.6 m telescopic ladder: For motorhomes up to 2.9 m high.

- 2.9 m telescopic ladder: For motorhomes up to 3.2 m high.

- 3.8 m telescopic ladder: For motorhomes over 3.2 m high.

Note: These are guide values and the optimum ladder height may vary depending on the vehicle. If you also want to use the ladder in the home, choose a longer ladder for additional flexibility.